CONTENT

- Definition

- Terminologies used in machines

- Types and examples

Machines make our work simpler. It is a force producing device by which a large force called load can be overcome by a small applied force called effort

Terminologies Used In Machines

1. FORCE RATIO (MECHANICAL ADVANTAGE )

2. VELOCITY RATIO

3. EFFICIENCY

MECHANICAL ADVANTAGE

We define effort as the force applied to a machine and load as the resistance overcome by the machine. The ability of a machine to overcome a large load through a small effort is known as its mechanical advantage .It is given by

M.A = Load/ Effort

The mechanical advantage of a machine is influenced by friction in parts

VELOCITY RATIO (V.R)

The velocity ratio is the ratio of distance moved by the effort and load in the same interval

V.R = Distance moved by effort / Distance moved by the load

The velocity ratio depends on the geometry of the machine

EFFICIENCY (E)

The efficiency of a machine is defined as

Ef = (Useful work done by the machine/ Work put into the machine) X 100

Work = force x distance

Ef = (load x distance moved by load / Effort x distance moved by effort) x 100

Then V.R =M.A

TYPES OF MACHINES

1. LEVER

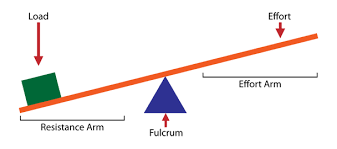

This is the simplest form of machine. It consist of a rigid rod pivoted about a point called the fulcrum F with a small effort applied at one end of the lever to overcome a large load L at the other end . There are various types of lever depending on the relative positions of the load, effort and fulcrum.

Taking moment about F

E x a = L x b which is given

L = a =M.A

E b

a/b = V.R

Examples of first class lever are the crowbar, pair of scissors or pincers, claw hammer, see-saw ,pliers etc

In second order lever , the load is between the fulcrum and effort

2. WHEEL AND AXLE

It consists of a large wheel to which a rope or string is attached and an axle or small wheel with the rope or string wound round it in opposite direction . The load to be lifted is hung at the free end of the rope on the axle while the effort is applied at the end of the rope on the wheel . For each complete rotation the load and the effort move through distance equal to the circumference of the wheel and axle respectively.

3. GEAR WHEELS

In gear boxes , there are toothed wheels of different diameter interlocked to give turning force at low speed depending on which gear is the driver and which is the driven

V.R = No of teeth on driven wheel ( A) / No of teeth on driving wheel (B)

4. THE HYDRAULIC PRESS

The machine is widely used for compressing waste paper and cotton into compact bales forging different alloys into desirable shape etc .It s work is based on Pascal’s principle which states that pressure is transmitted equally in fluid Oil is the liquid normally used in hydraulic press

V.R = R2/r2

5. THE WEDGE

The wedge is a combination of two inclined planes. It is used to separate bodies which are held together by large force .Examples of wedge type of machines are axes chisels knives etc.

M.A = X1 / X0 = Slant height of wedge / Thickness of wedge

6. PULLEY

A simple pulley is a fixed wheel hung on a suitable support with a rope passing round its groove.

BLOCK AND TACKLE (PULLEY)

This is the more practical system of pulleys in which one or more pulley are mounted on the same axle with one continuous rope passing all-round the pulleys

EFFECTS OF FRICTION ON MACHINE

Work is always wasted in machines to overcome the frictional forces present between the moving parts and also to lift to part of the machine. The greater the friction, the greater the effort required and the smaller the M.A. M.A depend on friction but depend on the geometry of moving parts.

The efficiency of nearly all the machines varies with the load and the load and effort are related by : E = al + b ( a and b are constant ).This is called linear law for a machine .It follows that E is proportional to L .The value to give us the effort required to operate the machine moving part only if no load is present while A gives us the measure of the friction present

= (M.A x 100) / V.R In practical machines the efficiency is usually less than 100% because of friction in the moving parts of the machine.

INCLINED PLANE:

This is in form of a sloping plank commonly used to raise heavy load such as barrels of oil with little applied effort than by lifting it vertically .

V.R = Distance moved by effort / Distance moved by load

= x /h ; V.R = 1/ sin θ

7. THE SCREW

Geometrically speaking the screw is an inclined plane wrapped round a cylinder to form a thread. The distance between successive threads on a screw is called its pitch. For one complete revolution of screw through an effort , the load moves a distance equal to its pitch e.g. screw jack nut and bolt

In a screw jack where length of the operating handle is a, the effort moved a distance equal to the pitch P.

Thus V.R= -2πa/P

= 2πr/P

If frictional forces are negligible

CLASSWORK

- (a) What is a machine? (b) Explain why a machine can never be 100% efficient.

- Define the following terms as applicable to machine (a) velocity ratio (ii) mechanical advantage (iii) efficiency

- A pulley with velocity ratio of 5 is used to lift a load of 400N through a vertical height of 8m by exerting an effort of 100N. Calculate the: (a) work done by the effort (b) efficiency of the pulley system

Read our disclaimer.

AD: Take Free online baptism course: Preachi.com